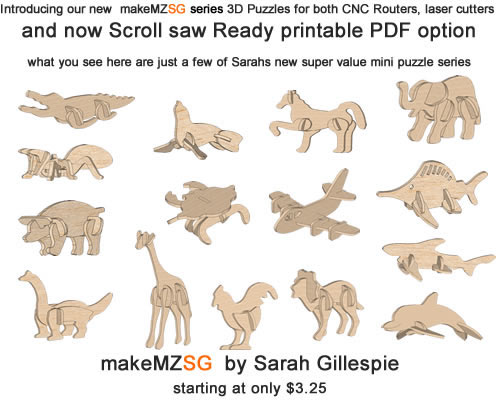

Welcome to our Scroll Saw 3d puzzle Pattern learning pages

Cutting makeCNC 3d Puzzle Models on Your Scroll Saw

3d Puzzle Models in general have two basic uses: To display as a decorative item or to use as an interactive toy.

If you choose to display your finished Model as a decorative item, consider gluing the pieces together and affixing the assembled Model to a sturdy base. A glued Model that falls from a shelf or mantel could sustain irreparable damage which is not fun when using more expensive materials, such as hardwoods or colored acrylic.

If you choose to use your finished Model as an interactive toy, be sure that the child is over 8 yrs of age. These models include some small pieces that can cause choking if swallowed by younger children. Also, be sure to choose a durable wood, such as cabinet-grade Birch plywood and a non-toxic finish.

makeCNC Scroll Saw 3D Puzzle Patterns come in both metric and imperial sizes to allow people from all over the world to enjoy cutting them out. If you are using our metric patterns then you should use the equivalent metric versions of measurements and tools described in this information.

Please read this important introduction before reading the rest of the tutorial.

This information is intended to give a basic introduction to cutting our puzzles and projects patterns using a Scroll Saw and is not intended as a replacement for training in how to use a Scroll Saw or basic woodworking tools.

There are many videos on You Tube explaining the basics of Scroll Saw setup and use.

If you have never used a Scroll Saw before we suggest taking a look at those tutorials and videos before attempting to make our projects. While they are simple to make, a basic understanding of Scroll Saw technique is required and, as always, you must follow common sense shop safety rules like wearing eye protection as well as protecting your fingers from the blade.

Printing the PDF of Your 3D Puzzle Patterns

Our Scroll Saw Patterns arrive in a zip file that needs to be uncompressed using

A program like winrar or the equivalent.

Winrar is available here:

http://www.rarlab.com/download.htm

It’s a free program and very handy to have installed on your system.

After you have uncompressed the files into a folder on your computer you will need to navigate to the folder to view the contents. There will always be two files in the folder and sometimes more. These will be PDF files and they will need the free Adobe Acrobat Reader installed on your computer to view and print them.

You can download Acrobat Reader free at Adobes website.

This program will allow you to print your PDF patterns. You have several options available when you print the pattern.

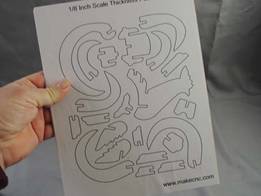

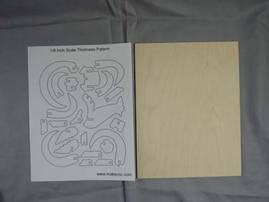

The images below are printed copies of our Rooster puzzle and are for the purpose of this tutorial. They are printed in color but you will more than likely want to print your patterns in black and white and not print the cover to save paper and ink. You do not need to print the assembly guide if you are comfortable reading off your PC, laptop or tablet.

In the PDF print options you will need to make sure that you have the print options set to print the pattern at the actual document size. This will ensure that your pattern prints will stay at the correct scale to make the slot sizes correct for the thickness of material you use.

If you would like to cut the patterns from thicker or thinner material than the standard 1/8th or 3mm size that the pattern comes in then you will need to calculate the % increase or decrease you need to set the print out to in your print options to make the slots and tab sizes correct for the thickness of material you are cutting. For example, if you increase the size of the printout by 100% on a 1/8th pattern you will have a printed pattern for ¼ inch material and so forth.

The option to do this will be presented in the print options when you go to print out your PDF patterns. In Windows this will be under the button that says “poster” in your print options.

Material Choices

The Scroll Saw is a versatile tool, able to cut a variety of materials. Usually the type of wood used to cut out our patterns is from cabinet-grade Birch plywood. This type of plywood can be left unfinished for a light tan, almost bone color, or it can be stained to resemble cherry, walnut, pecan or any other number of hardwoods. The pieces can also be painted, however, frequent disassembly and reassembly will cause the paint at the joints to wear and flake. You may also want to try staining and clear coating. There are numerous finishing techniques to try

and you will find more of these being added all the time in this and other areas of the makeCNC website.

A second option is to cut the 3D Puzzles from hardwood. Walnut and cherry are highly recommended. The tight grain of these woods makes them ideal choices for these types of patterns. Woods with a coarse grain, such as oak, should be avoided as it becomes brittle and has a tendency to break.

.

A third option is to try a non-wood material such as Corian, commonly used for kitchen and bathroom countertops, or acrylic. Both of these materials come in a wide variety of colors which can produce some spectacular results.

How to Use the PDF 3D Puzzle Patterns

The pattern PDFs are usually supplied at their actual size and are arranged to fit 8.5” X 11” boards.

After printing them out on your laser or inkjet printer you will need to fix them to your material because each of the pattern pieces fit together with 1/8” thick wood. Be sure to measure the thickness of the material prior to cutting the pieces. If the material is slightly larger or slightly smaller than the slots on the patterns, adjust the slots to the exact thickness of the material by printing the patterns at a slightly larger or smaller scale or by offsetting from the line a small amount when you are cutting the slots with your scroll saw. I recommend the first method for the best results.

Patterns can be affixed to the material in a variety of ways. At makeCNC we use repositionable contact adhesive. It is clean, easy to use and has a remarkably strong hold. Another possibility is repositionable photo spray or double-sided tape.

Scroll Sawing TIP:

Coat your wood with blue painters tape first. Then apply your pattern to that. You will get no residue on the wood, and it doesn't matter if you put too much glue on the pattern as the painters tape comes off every time.? Works like a dream!

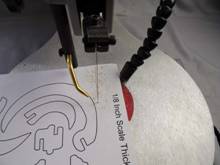

Cutting the Pattern Parts Out with Your Scroll Saw

You are now ready to begin cutting the pattern parts. First cut it down into several smaller pieces before you begin to cut the individual parts. This will give you more control over the board and increase the accuracy of your cuts

GEAROTIC MOTION GEAR MAKING SOFTWARE CAN MAKE PDF PRINTOUTS OF GEARS FOR THE SCROLLSAW

THE CLOCK IS TICKING CHECK IT OUT NOW

|